Shop floor: more than just an ERP extension

Shop floor management. Every manufacturing company that wants to accurately plan and track what is happening in production departments, needs a shop floor system. There are many systems available, each one with its own pros and cons. Based on a long history and deep experience with manufacturing and logistics systems, Vanenburg will soon be launching a Shop floor solution with unique capabilities. In this blog, I will explain what a shop floor application does and why we believe we will set a new standard with the Rappit Shopfloor solution.

Back to the core: ERP

Enterprise Resource Planning (ERP) solutions are necessary for every company where inventory control, planning, purchasing, manufacturing, delivery management and invoicing occur. The process starts when an order comes in and the required inventory of raw materials and parts are purchased if not in stock already. After that, a planner defines what operations must be executed on which machines. Usually, a product must go through different machining operations before it’s fully completed, such as laser cutting, hole drilling, and welding. This is a typical production process where the Rappit Shopfloor application streamlines operations.

What is a shop floor application?

Let’s get to the core topic: What is a shop floor application? A shop floor application is responsible for smoothly executing planned work orders in production to finished products or parts. In a shop floor application, the factory worker can find detailed information about the pending work orders, such as required parts, and the necessary manufacturing or assembly operations. In addition, the worker will book labor hours on the work order.

In some factories, every machine has a designated workstation with designated workers. In other factories, a workstation can serve multiple machines and workers. The shop floor application will orchestrate which operations are performed by workers and machines, and in which order.

Why not just use ERP?

After all of this, you might ask why this functionality isn’t available in the ERP system by default. We would like to have it all in one package without worrying about syncing data back and forth. There are several reasons why this isn’t the case

First, we must go back to understand why a shop floor application was invented. In the past, everything in the factory was done on paper. From printing out work orders to keeping track of their hours on paper, if there was a problem, factory workers had to call the planners or walk to their workplace to get access to the ERP system. These systems were typically built with the intent of using them in office settings, not on screens in the factory.

In contrast, a shop floor application is built precisely for this purpose. Standard ERP systems do offer quite some functionalities to direct the shop floor. They tell which parts are needed for which operation and which machine. However, they usually don’t generate instructions for moving parts from operation A to B. On top of that, they do not provide the most optimal route of operations based on which machines are available at that specific moment. Optimizing such a route leads to the most optimal takt-time and a lower takt-time improves the department productivity.

Secondly, an ERP system typically displays a lot of data on the screen. You see work orders, supplier information, customer information, inventory levels, etc. Much of this information is irrelevant to the worker on the shop floor, whereas a well-optimized shop floor system should only show relevant information to the user.

Exception management

In a factory, unforeseen exceptions can occur during manufacturing process. The shop floor application should ease the communication with the planner, for example, to ask the planner for more details about a work order. If the same problem occurs multiple times, an action point is communicated to the planners. This way, a shop floor system helps workers to identify and reduce problems and optimize the manufacturing or assembly process.

Optimization of processes

Given that a shop floor system is meant to optimize the production or assembly processes, machine learning (ML) and artificial intelligence (AI) can play a useful role. Using advanced algorithms, an AI/ML system can predict if a work order is likely to have problems, allowing planners to make adjustments before the operations start. In addition, AI/ML can help identify focus areas for streamlining a factory. For example, an AI system notices an area where parts are sitting idle for quite some time after welding. Additional resources can be assigned to packaging to improve this process. The possibilities are endless.

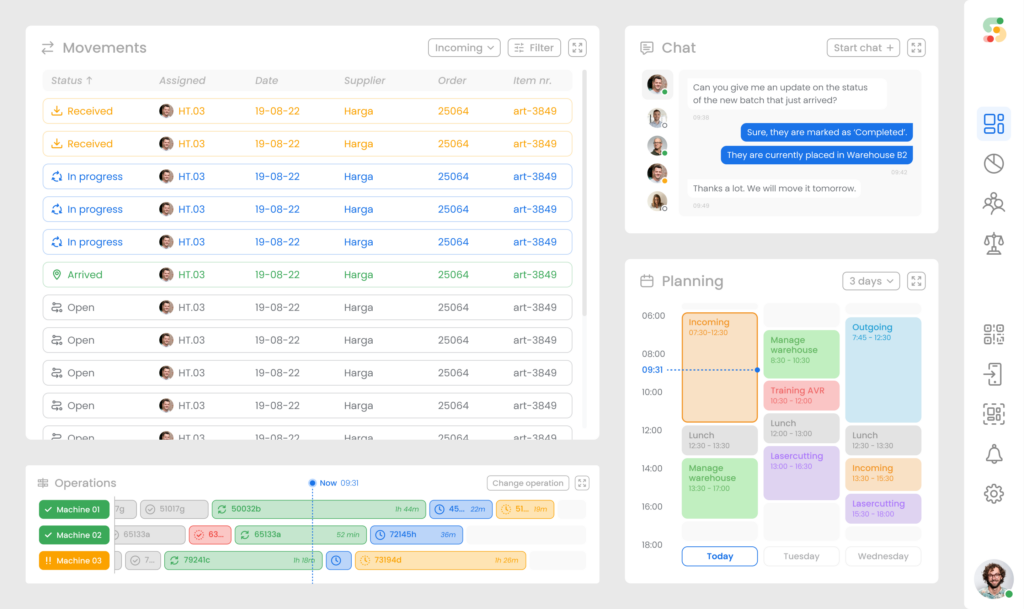

Screenshot of Vanenburg’s Shop floor solution

How is the Rappit Shopfloor solution different from the others?

Vanenburg has a long history in manufacturing, ERP, and process optimization. Using this experience, we have developed a shop floor system that differentiates itself from other shop floor applications in many ways.

As mentioned earlier, most shop floor applications use busy and confusing displays.. It’s like looking at an Excel sheet with too many columns and rows, creating confusion instead of providing useful information. A user may work at multiple workstations in a factory and need different information at each location. The Rappit Shopfloor application only displays the relevant information for a given combination of user, location and time.

Furthermore, our solution has a UI optimized for touchscreen. There is no need for any paper or keyboard, whereas other solutions are still behind by not providing the touchscreen option, and are not working properly.

And finally, the Rappit Shopfloor application is running on the Google Cloud Platform to ensure high availability and scalability. It has a useful offline mode to ensure that a user can continue working when a network connection temporarily drops out, e.g., while moving from one location to the next on a forklift. When the connection is re-established, all actions are immediately synchronized with the application in the cloud.

Conclusion

I hope you just learned more about the role of the shop floor application in an ERP and how we envision a more efficient solution for manufacturers. Of course, there is much more to tell about this subject. In the future, we will release more technical blogs related to this topic and dive deeper into the actual pain points, and challenges you face in the manufacturing process. Ultimately, our goal is to support you and your business in making your work easier and more efficient and that you have fun doing it!

Feel free to contact us for more information about shop floor and the possibilities for your business.